Unlocking Business Success in Metal Fabrication: The Definitive Guide to CNC Lathe Parts Suppliers and Industry Excellence

In today’s rapidly evolving manufacturing landscape, metal fabrication stands as a cornerstone of industrial progress, driving forward innovation, precision engineering, and economic growth. For businesses operating within this dynamic sector, choosing the right metal fabricators and sourcing the best cnc lathe parts suppliers are critical steps toward establishing a competitive edge. At deepmould.net, we pride ourselves on being a leading provider of custom metal fabrication services, specializing in high-quality CNC lathe components that meet and exceed industry standards.

The Critical Role of Metal Fabricators in Modern Industry

Metal fabricators are the backbone of countless industries, including automotive, aerospace, medical devices, construction, and electronics. Their ability to transform raw materials into precise, functional components enables innovation and productivity across sectors. With advancements in technology, modern metal fabricators incorporate sophisticated machinery—such as CNC lathes, mills, and robotic systems—to enhance accuracy, repeatability, and efficiency.

Why Precision and Quality Matter in Metal Fabrication

In an era where tolerance levels are minimal and product performance is paramount, the quality of metal fabrication directly impacts the longevity and reliability of end products. Whether manufacturing intricate engine parts, structural components, or delicate medical implants, precision is non-negotiable. This is why businesses must partner with reputable metal fabricators and trusted cnc lathe parts suppliers.

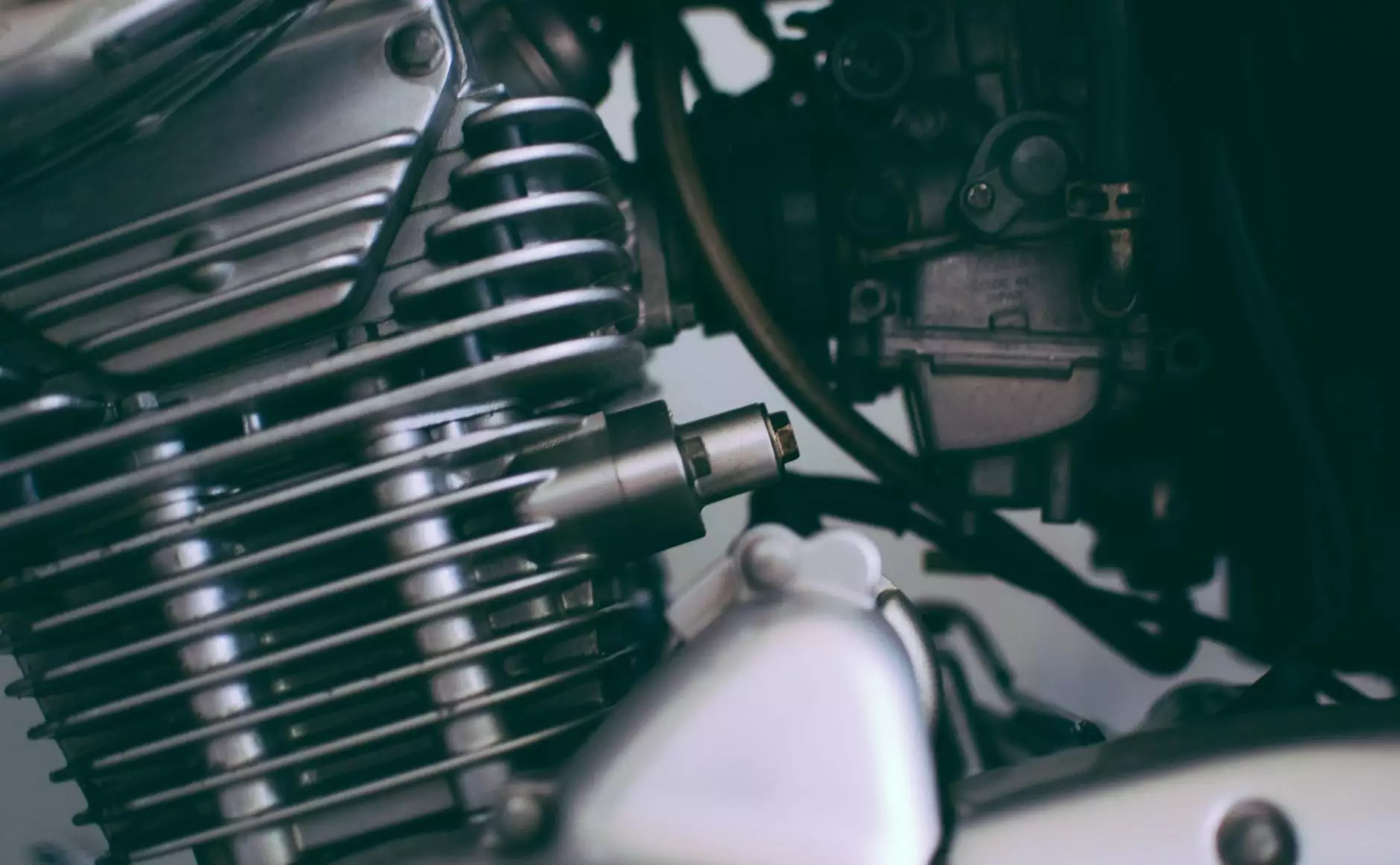

Understanding CNC Lathe Parts and Their Significance

CNC (Computer Numerical Control) lathes are vital automation tools that produce high-precision cylindrical components through automated, computer-controlled processes. The cnc lathe parts include a complex array of tools, spindles, chucks, and guideways, all of which require meticulous design and manufacturing to ensure flawless operation.

The Evolution of CNC Technology and Its Impact

Over recent decades, CNC technology has revolutionized metalworking. It allows for rapid prototyping, batch production, and complex geometries that would be impossible with manual methods. For metal fabricators, having access to top-tier cnc lathe parts suppliers is essential for maintaining machine accuracy and consistent output, thereby safeguarding quality and productivity.

Choosing the Right CNC Lathe Parts Suppliers for Your Business

Supplier selection is a pivotal decision impacting your manufacturing efficiency and product reliability. The ideal cnc lathe parts suppliers should demonstrate:

- Experience and Industry Reputation: Proven track record in providing high-quality components.

- Technical Expertise: Deep understanding of CNC machine requirements and specifications.

- Material Quality: Use of premium raw materials such as high-grade steel, carbide, and alloy composites.

- Customization Capabilities: Ability to produce tailor-made parts suited to specific machinery models.

- Reliable Delivery and Support: Fast turnaround times and excellent after-sales service.

Innovative Manufacturing Solutions from DeepMould.net

At DeepMould, we understand the importance of precision in metal fabrication and supply chain reliability. Our company specializes in providing comprehensive metal fabricator solutions, including sourcing high-grade cnc lathe parts that meet the highest standards of quality and performance.

Our Offerings and Capabilities

- Customized CNC Lathe Components: Precise, custom-engineered parts tailored to your specific machine models and production needs.

- Material Diversity: A wide selection of raw materials, including stainless steel, aluminum alloys, brass, and specialty composites.

- Advanced Machining Technology: Utilization of state-of-the-art CNC machines to ensure optimal tolerances and surface finishes.

- Quality Assurance: Rigorous inspections, certifications, and adherence to international standards such as ISO 9001.

- Competitive Pricing: Cost-effective solutions without compromising on quality.

Engineering and Design Support for Seamless Supply Chains

Effective metal fabrication depends not only on quality components but also on robust engineering support. DeepMould.net offers comprehensive design assistance, enabling clients to optimize their parts for manufacturability and performance. Our team collaborates closely with customers to develop custom solutions that enhance efficiency, reduce costs, and prolong equipment lifespan.

Advantages of Partnering with DeepMould

- Unparalleled Quality Control: Every batch of cnc lathe parts undergoes strict inspection to eliminate defects.

- Fast Turnaround: Minimizing downtime through rapid prototyping and production cycles.

- End-to-End Service: From initial consultation and design to delivery and after-sales support.

- Global Reach: Capable of serving international markets with consistent quality standards.

- Environmental Responsibility: Commitment to sustainable practices and eco-friendly manufacturing processes.

Market Trends and Future Outlook in Metal Fabrication

The metal fabrication industry is experiencing unprecedented growth driven by emerging technologies such as additive manufacturing, Industry 4.0, and IoT integration. A key trend is the increasing demand for highly customized, lightweight, and durable components, which elevates the importance of high-quality cnc lathe parts from dependable suppliers.

Moreover, the globalization of supply chains necessitates reliable sourcing from trusted metal fabricators. Companies that actively invest in advanced CNC equipment and foster strategic partnerships with skilled cnc lathe parts suppliers are better positioned to adapt to rapidly changing market conditions.

Strategic Tips for Growing Your Metal Fabrication Business

Achieving long-term success requires a focus on continuous improvement, innovation, and customer satisfaction. Here are some strategic tips:

- Invest in Technology: Continually upgrade your machinery and automation systems to stay ahead of competitors.

- Build Strong Supplier Relationships: Partner with reliable cnc lathe parts suppliers who can provide consistent quality and technical support.

- Prioritize Quality Assurance: Implement strict inspection protocols and certifications to enhance credibility.

- Expand Service Offerings: Diversify into value-added services such as surface finishing, assembly, and custom design.

- Focus on Sustainable Practices: Adopt eco-friendly methods and materials to meet environmental standards and appeal to eco-conscious clients.

Conclusion: Building a Resilient and Competitive Metal Fabrication Business

The pathway to success in the metal fabrication industry lies in strategic sourcing, technological investment, and continuous quality improvement. Choosing the right cnc lathe parts suppliers like DeepMould can significantly enhance your operational efficiency, product precision, and market competitiveness.

Embracing innovation, fostering reliable partnerships, and maintaining unwavering commitment to quality will empower your business to thrive in a competitive environment. Whether you are expanding your current capabilities or entering new markets, the key lies in leveraging the best materials and technologies supported by industry-leading suppliers.

At DeepMould, we are dedicated to helping your business succeed by providing superior metal fabricator solutions and high-grade cnc lathe parts that set you apart from the competition. Contact us today to discover how we can support your growth ambitions and deliver excellence in every component manufactured.